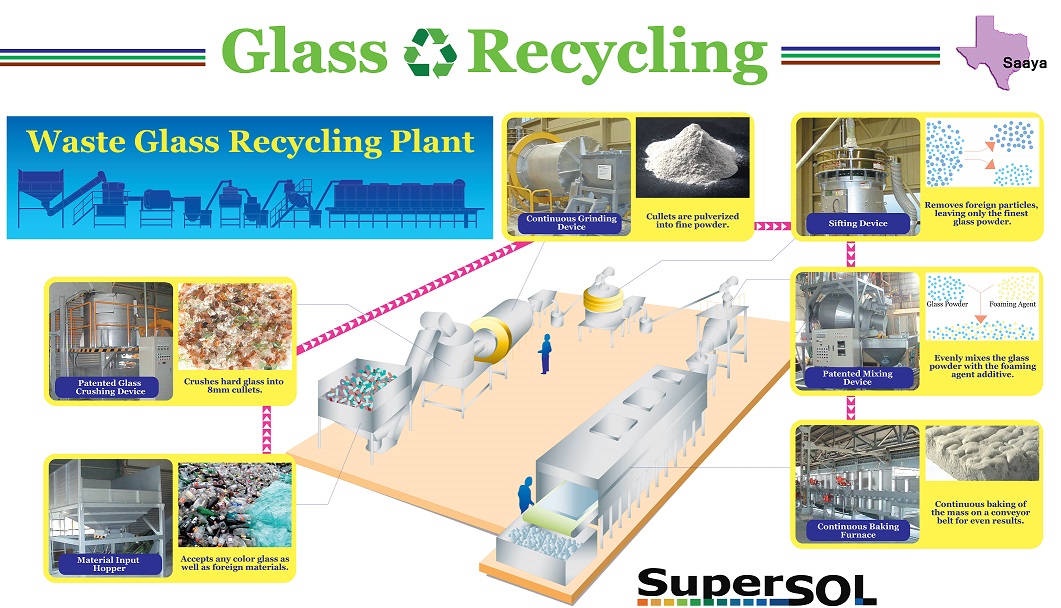

Factory Overview

Raw Material Hopper

The raw material hopper can hold 4.5 cubic meters of glass (approximately 3.9 UStons). The glass passes through the vibrating cutter at the bottom of the hopper and is discharged on a conveyor belt.

Glass Crusher

Waste glass that enters the crusher off of the conveyor is crushed to under 6mm in one process with this compact Φ1,600mm crushing machine.

The glass crusher utilizes a compression crushing system. This technique applies the principle of millstone grinding in a rolling rotation resulting in compression crushing. There are also special steel and detachable couplings fitted inside to improve its abrasion resistance. These unique features have achieved better resistance and durability compared with former glass crushing machines. (Patent obtained)

Cullet Crusher

The glass crusher produces cullets less than 6mm in size. The next process is to make these cullets into powder. The median powder particle size is about 35μm. The cullet crusher was developed from tube mills specifically for glass cullets. The shape of the inlet allows any shape of glass granule to be entered into the machine smoothly. Then, the powder is discharged in order from the lightest to the heaviest. The double-deck hopper can classify labels or other paper products inside.

Aluminum balls inside the cullet crusher effectively turn the glass into powder, and the machine can work without maintenance for two years. Glass powder can be manufactured continuously by using full automatic functions, operating the glass crusher and the cullet crusher simultaneously. We were able to achieve over 97% granule-size stability as well as operation optimization.

Vibrating Sifter

The sifter unit classifies the sizes of granules sent from the cullet crusher and extracts powder that meets the size regulation.

This unit is connected to the powder transferring unit so the classification process can be completed seamlessly. It is fully closed and won't cause any dust scattering issues.

Powder Transferring Apparatus

This is a device for tranferring powder from the cullet crusher, vibrating sifter, and mixer.

The powder transferring unit is a spin-flow conveyor and it applies the principle of whirlpools. This unit has achieved full automation and stable powder transfer, which were said to be difficult to realize. It completely shuts down the flow of air inside, and there is less chance of static interruption. The process is absolutely free from dust scattering problems.

Powder Mixer

The powder mixer blends glass powder sorted in the sifting unit and two kinds of additives automatically.

It can stir any materials equally even if they are different in quality, weight, and shape. It is a continuous batch machine and can create up to 350kg of blended powder per operation. All the processes, such as powder feed, measuring, and input, are automated so that two additives can be mixed without interruption, and the blended powder can be produced stably.

Firing Furnace

Porous-lightweight-foamed material (Supersol) is produced by firing a blended powder produced by the mixer. The furnace bakes the powder at temperatures between 700℃ to 920℃. The 15mm thick glass powder expands to approximately 60mm by the end of the baking process.

The furnace consists of a firing unit and a cooling unit composed of lightweight insulation and a fire resistant structure. It is capable of continuous firing with the wire mesh belt conveyor. Additionally, there are different sections inside of the furnace, such as preheating, softening, firing, and foaming. A retention combustion method is used with three-position control by the burners.

Supersol Sorter

This unit breaks down the Supersol and sorts according to the size to fit the purpose of the application. The shape and quality of the crushing blades were invented specifically for Supersol. They make the crushing and sorting process effective.

Electricity Usage